Copyrights NEXYAD 2005-2006 all rights reserved

Terms of use of images and graphics copied from this page : Policy

Keywords

: rain machine, artificial

rain, wiper systems efficiency measurement, visibility through the

windscreen,

drops on the windscreen, programmable lights and rain, car industry,

rain sensors, rubbers wipers, visual quality score, distance of

visibylity, distance of detection, RainNexTM,

DropNexTM,

VisiNexTM,

Wiper systems tester

| NEXYAD

has developped integrated systems that can work together and allow to

test in a quantitative way wiper systems (including mechanical parts,

rain sensors, and intelligent heuristics). Instead of "waiting |

for the

rain" in order to test a new wiper system, it is now possible to

generate scenarios of light and rain (reproductable) and to estimate

how the wiper system helps to recover visibility when the lack of

visibility is due to the rain laid on the windshield. |

Qualitative feeling of "good wiping" is replaced with

quantitative

scores (that were demonstrated to be highly correlated with humain

sensory feeling). NEXYAD tools are in use in the Automotive industry

(car manufacturers and rain sensors or wipers providers). |

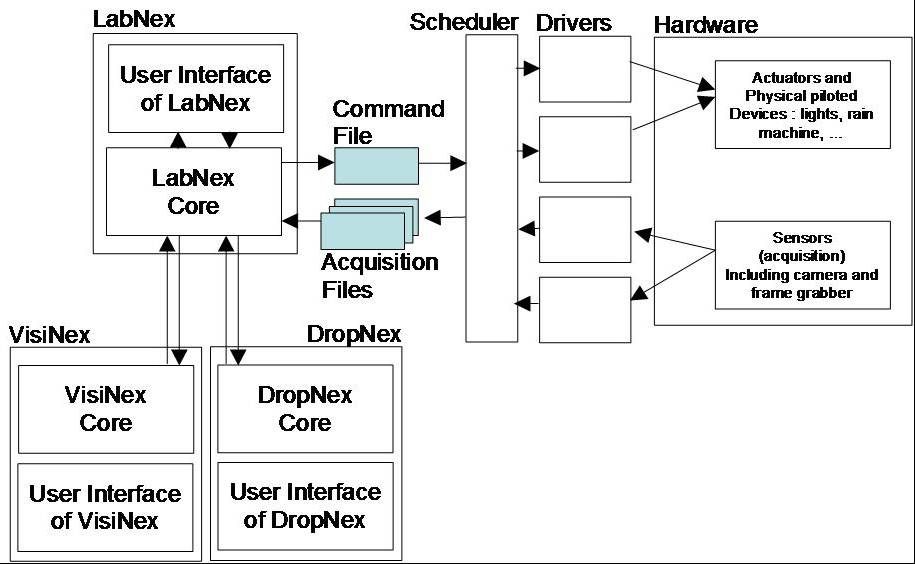

- Open hardware and software architecture :

|

The

NEXYAD open architecture lets you the choice :

-

you may integer our application softwares (such as VisiNex or

DropNex, see further) into your architecture (as soon as you feed them

with the proper expected and documented format),

-

you may integer your hardware components (example : rain

machine, wind machine, lights, ...) into our architecture and let them

be piloted by our environment,

|

-

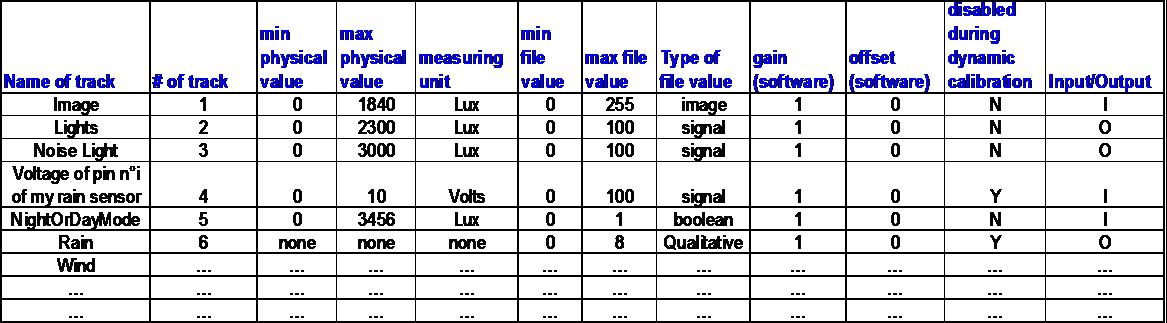

you may buy our complete system, LabNex

lets you declare every intput and output for the

application (with their name, physical unit, min and max values, ...)

and lets you draw chronograms for every piloted output (example : rain,

light, wind). LabNex reads and writes script files (format documented).

The

Scheduler reads the script files and builds the real time loop for

acquisitions (signals, image

|

real

time loop for

acquisitions (signals, image sequence, ...), and piloting (rain,

lights, wind, ...). The acquired data (images, signals, ...) are

recorded into files. The Scheduler is the only brick that is hardware

sensitive (it is linked with the hardware drivers).

The

application modules (VisiNex and DropNex) read these files, and

compute technical results (see further). They generate .csv ASCII files

(so you can plot your results with regular tools).

|

- RainNexTM :

RainNexTM

is a rain machine that generates

artificial rain very similar to natural rain. RainNexTM

is programmable and generates reproductables chronograms of rain and

light (option : important because influence of rain on visibility also

depends on lights values) ... NO NEED TO WAIT FOR THE RAIN ANYMORE ! |

Functional

important

characteristics of RainNex :

- can generate with 1 "rain generator head", up to 216 different kinds of rain - homogenous rain with a given size of drops and a given stream flow - heterogenous rain with different kinds of drops (size and stream flow) mixed together : example : thin rain with some big drops falling from the trees. - no ON-delay, no OFF-delay :

going from a rain to another is almost intantaneous.

- can be used with 2 (or more) synchronized rain generator heads (example : one for the rain sensor area, one for the VisiNex or DropNex measurement area) : because heads are mobile, it is easy to test several locations for your rain sensor (for instance). |

- can run a complex sequence of rain - highly statistically reproductable rain (reproductibility of RainNex or any other rain machine can be tested with DropNex - see below). - pilotable by any real time scheduler |

- LabNexTM :

| LabNexTM

is a software module that lets you declare every input and output of

your applications : Then, for every output variable, LabNex lets you plot chronograms that will pilot the hardware device (example : rain, light, wind). Chronograms are made of elementary chronograms called "phases". The user can then manipulate phases together in order to build higher level chronograms called "scenarios". |

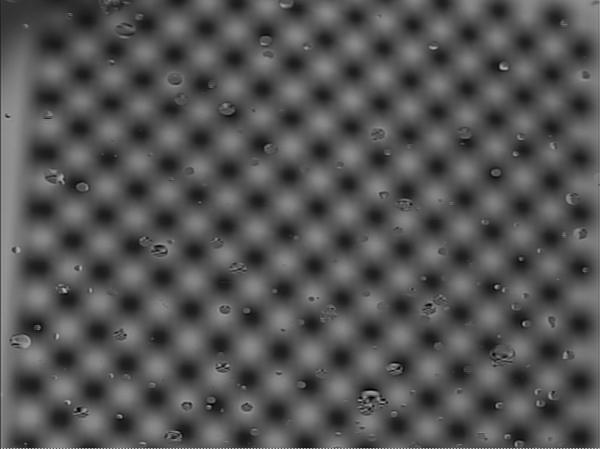

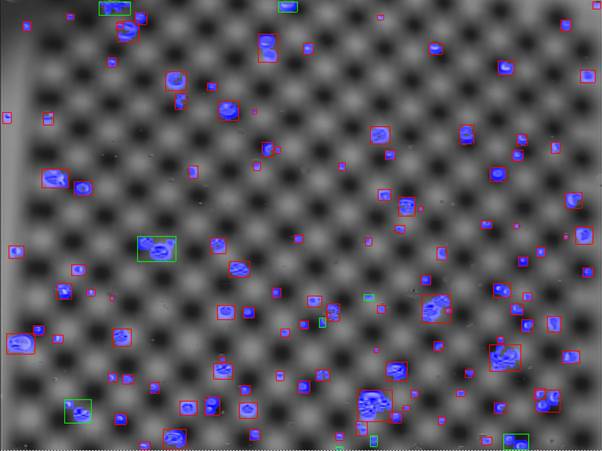

- DropNexTM :

acquired image at

time t

|

detection image at

time t

|

| DropNexTM

is an artificial vision-based system that acquires images focused on

the windscreen, and

computes among time, parameters such as : number of drops, size of drops statistics (mean, standard deviation, ...), ratio of wet surface (water may flow on the windscreen without making drops ...), ... Water is detected and a classification allows to recognize drops from running water or big clusters of drops. DropNexTM also lets you acquire signal from your own systems (example : if you are a rain sensors provider, you want to know, for every rain characteristic, which value are taken by every internal variable of your sensor ...). DropNex was made to control and measure rain coming from a rain machine (ex : RainNex) in a Laboratory. But recently, a new version of DropNex also allows to make measurements OUTSIDE ! (while regular driving) |

It means that

representativity of artificial rain can now be estimated in a

quantitative way (if statistics of your artificial rains are similar to

statistics of natural rains, you are sure that tests in the Lab are

valuable).

You need DropNex if you wish to buy a rain machine : |

- write the technical specifications of the expected rain machine

(you measure natural rains ootdoor, and you wish to generate artificial

rains that a statistically similar ...) : your task book is completely

clear. - validate a rain machine : once your supplier delivers the rain machine, you can test it in order to make sure that the desired rains can be generated. - tune a rain machine : during tests, you may want to generate a new kind of rain (that you found as being an interesting kind of natural rain). So you can use DropNex in order to measure the statistics of your aritificial rain (you tune the technical parameters as long as you don't have the expected rain statistics). |

- VisiNexTM :

|

VisiNexTM

is an artificial vision-based system that acquires calibrated images through

the windscreen and runs a model of

humain vision that leads to an estimation among time of visibility

descriptors such as : distance of detection, distance of recognition,

visual quality score,

...

|

NEXYAD has been involved in military research for more than 10 years and our VisiNex system is based on a human vision model that is highly correlated to human any regular panel "feeling" : a score of visibility (computed by VisiNex) is reproducable among time and is the same for 2 VisiNex systems at 2 different locations => you can use VisiNex as a communication tool between 2 engineering teams (example : customer, and provider). |

On the following graphics, one can see the influence of rain

(laid on

the windscreen) on the visibility through the windscreen, among time

(no wiping).

Rain level 1 is a very thin rain (low flow), and rain level

6 is a

storm rain.

|

The wiper system allows to recover a part of this

visibility

|

One

can clearly see that wipers recover visibility :

the left wiper

wipes from right to left, and visibility increases up to 80%.

Then the right wiper that moved in the same way pushes a cluster of water in front of VisiNex detection area and VisiNex detects a reduction of visibility. At least, the left wiper wipes from left to right and recovers visibility again. During the time between two wipings, visibility decreases ... This is a typical visibility pattern evolution for classical wipers cycle. NB : this way of testing wiper systems clearly considers the wipers as a way of recovering visibility : the "function" is to guaranty a good visibility |

through

the windscreen for every regular driving situation

(night, day, rain, fog, snow, ...). Wipers are an acceptable way of

recovering visibility in the case of rain. VisiNex directly "measures" visibility. It means that : - you can test the whole complex wiper system at a time (including rubbers, electric motors, rain sensor, light sensor, decision making software, ...), - you can test one element of this complex system (example : the rain sensor, or the rubber) : if the only point that changes from a measurement to another is the element (example : the rain sensor, or the rubber) for reproducable scenarios of rain and light, then the variations of visibility will be interpreted as being due |

to

this element (it means that design plans

can be used in order to tune the efficiency of every technical element

of the wiper system).

-

you can use the same technology to test the efficiency of other

technical ways of recovering visibility (example : lightning systems,

anti-fog lights, ...).

VisiNex

is "wiper technology unsensitive" : if you replace the rain

sensor with a camera, or if you replace the rubber with a field of

ultra sound waves, ..., you will still have to make sure that

visibility through the windshiel is acceptable.

|

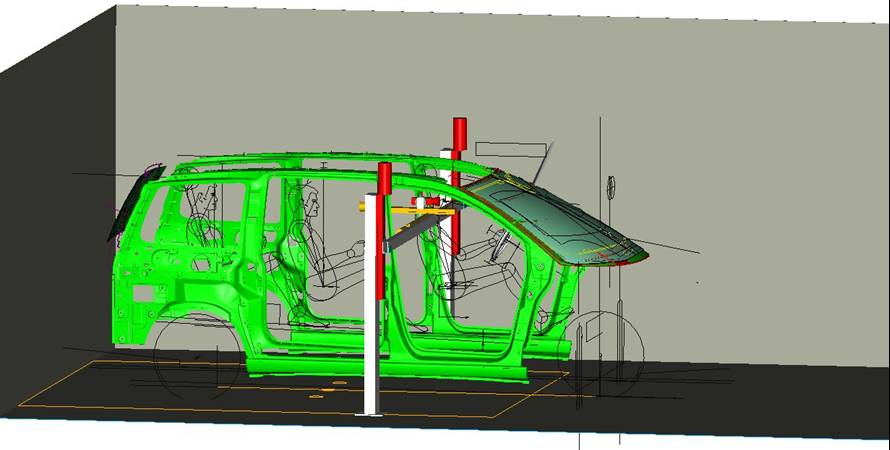

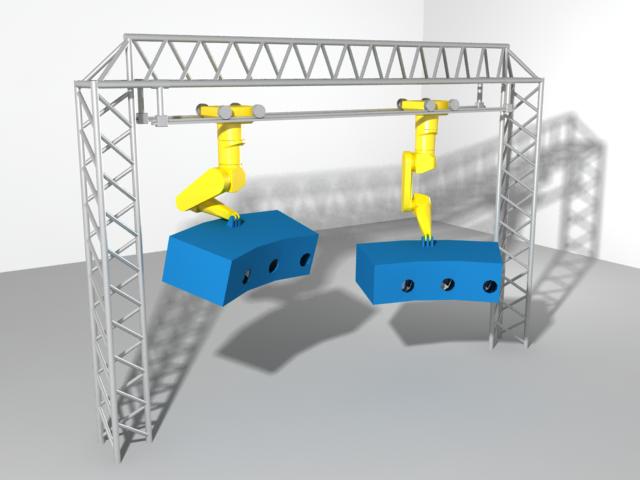

- Camera robot for VisiNex:

|

The camera used to grab images for VisiNex

can be

automatically moved inside a car at reproductable locations with a 3

axis motorized robot that crosses the car from right to left. This

robot is declared as an output device into LabNex.

|

|